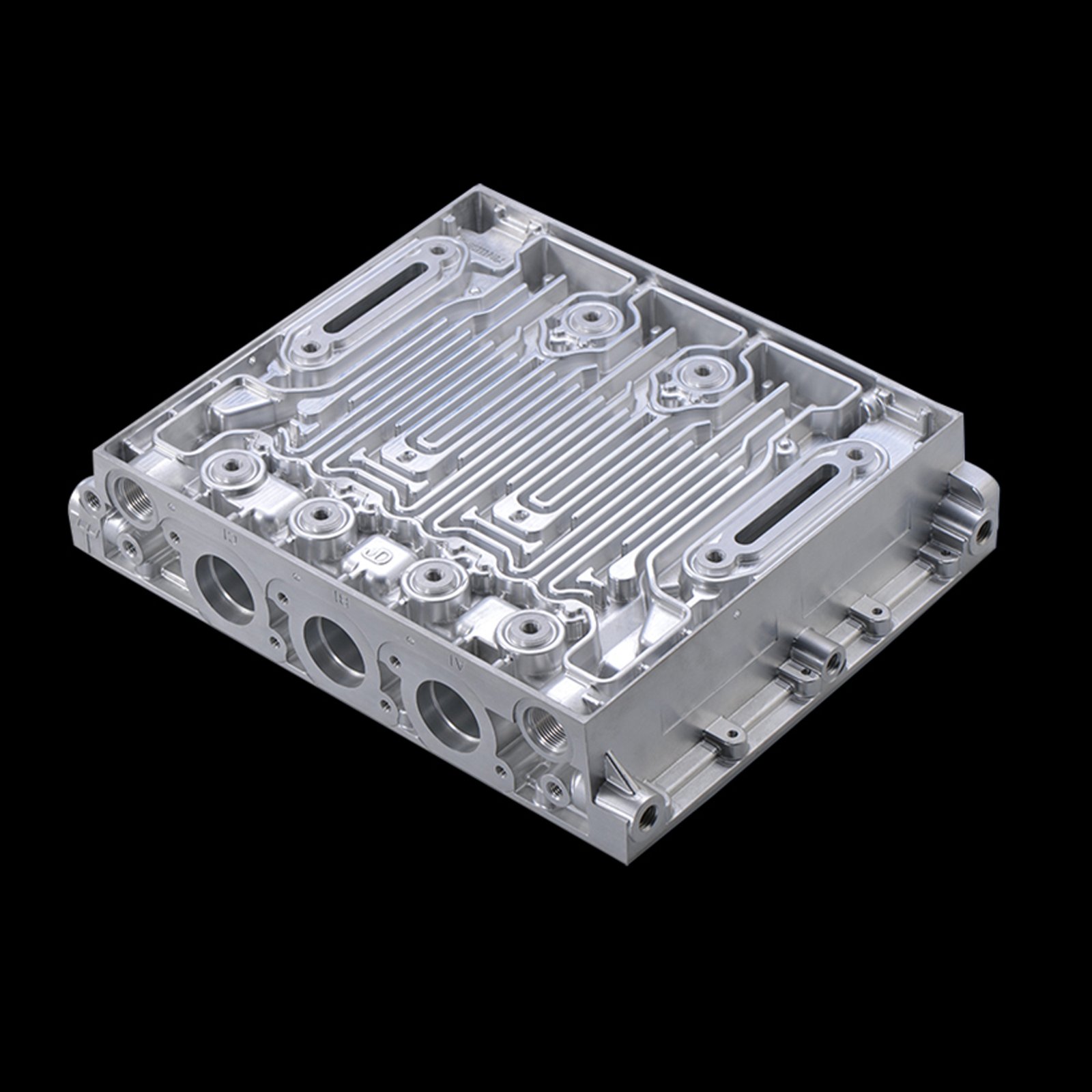

Injection molding

Custom injection molding for prototypes, new product introduction and production parts. DFMHUB offers a wide range of plastic injection molding processes, along with 25+ materials and surface finishes to meet your unique needs.

Our Capabilities

Rapid tooling

We use Aluminum moulds with a life time of up to 20,000 runs. This method is only for small quantities, providing design flexibility, that helps in cost-efficient tooling and accelerated manufacturing

Production Tooling

Production Tooling – Ideal for mass production of injection molding parts with the significantly higher tooling cost but has significantly cost per unit. The lead-time for production tooling usually takes around 3-4 weeks.

Single / family molds

Simple & Multiple cavities are machined into the mold tool. This allows for more parts to be produced per shot, minimizing the unit costs.

Mold Making

DFMHUB specializes in manufacturing mold for your plastic part

production be it prototype mold or production mold.

Your Injection molding Partner

Materials Available

Highly Recommended ABS, Nylon (PA6), Polyurethane, Acrylic, polyethylene, polycarbonate, Delrin

Manufacturing Partners

Get to choose from our distributed network of Injection molding partners across India.

Parts Manufactured

No of parts manufactured through our network of Injection molding services.

Certifications

DFMHUB is an ISO 9001: 2015 certified company and our Our manufacturing partners are (ISO 9001, ISO 14001, IATF 16949, ISO 27001)Certified.

Our latest Clients

FAQ

Injection molding is a manufacturing process for producing parts by injecting

molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals for which the process is called die-casting

Material for the part is fed into a heated barrel, mixed using and injected into

a mould cavity, where it cools and hardens to the configuration of the cavity.

We offer Rapid tooling, Production tooling, Multi-cavity molds, family molds, Insert

molding, Inset molds with a mini lead time of 2-3 weeks (Rapid tool), 4-5 weeks

(Production tool) Minimum order qty of 1000 parts.

ABS, Nylon (PA6), Polyurethane, Acrylic, polyethylene, polycarbonate, Delrin.

Available surface finishes for injection molding like glossy, semi glossy, matte, textured finish, as machined finish.