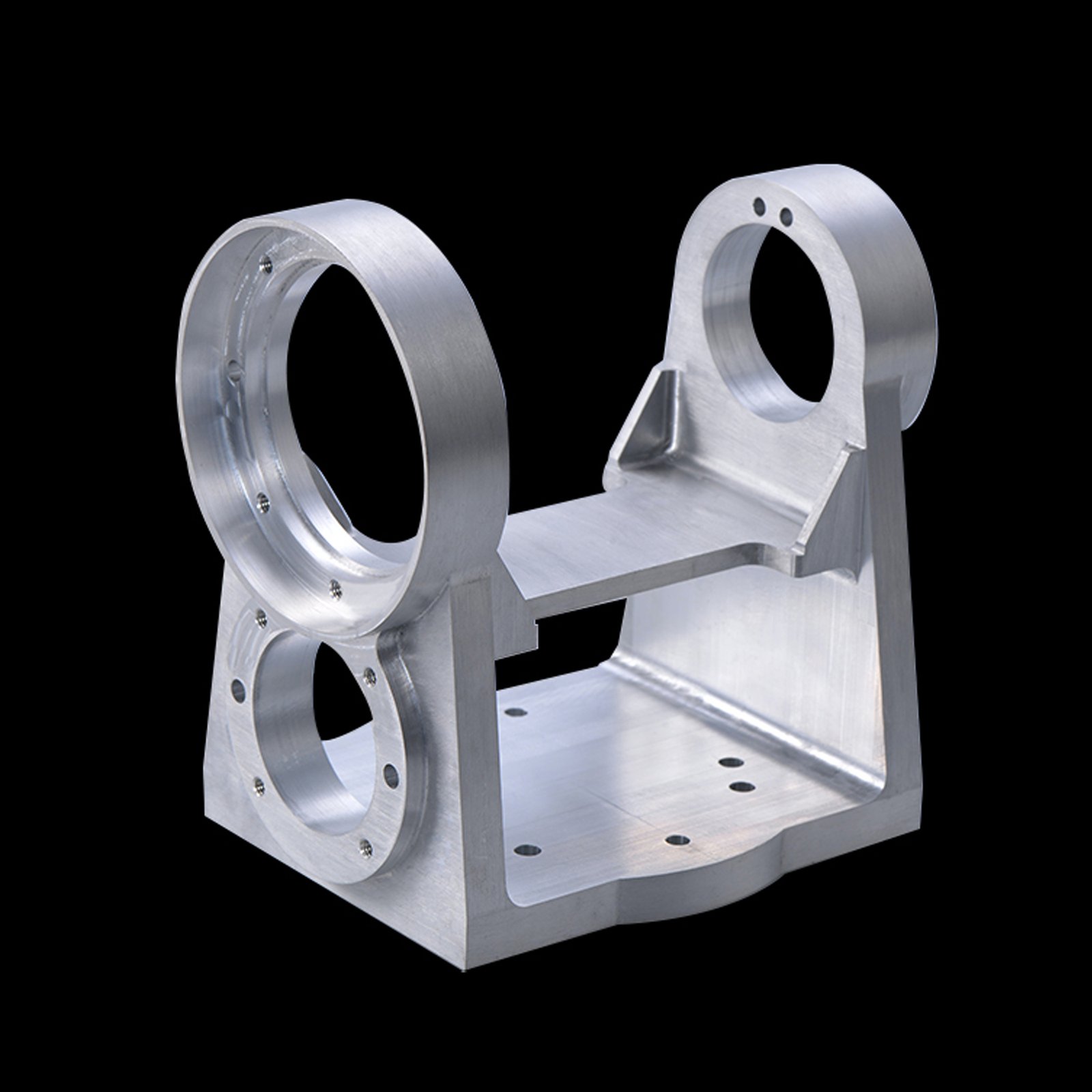

Custom Sheet metal fabrication Services

Fabrication Services

DFMHUBS offers on-demand sheet metal parts engineering and manufacturing services for low volume prototypes to high volume production and assembly.

Our Manufacturing Capabilities

Cutting

We offer a wide range of sheet cutting services like laser cutting,

Waterjet, and plasma cutting for high accuracy, versatility, and durability, capable of cutting material up to 50mm thick.

2.Punching

We offer a wide range of CNC punching services to press material

into the desired shape, creating either a hole or an indentation. Our machine punches sheet from. 5mm-6mm thickness.

Bending

We offering forming methods to bend materials into specific shapes or angles along a straight axis. Metal folding capacity range Up to 200 tons with bending length Up to 2500 mm Maximum thickness Up to 10 mm.

Sheet metal Welding

we provide welding services for parts manufactured to

assemble them into finished components. We offer TIG, MIG, Co2 welding processes based on the assembly.

Your sheet metal stamping Partner

Materials Available

Aluminum : 6061, 6063, 5052, 5754, Stainless steel : 202, 304, 316 , MS – En8, En24, 1018, Copper – Commerical & EC Grade

Stamping Partners

Get to choose from our distributed network of sheet metal fabrication partners across India.

Parts Manufactured

No of parts manufactured through our network of sheet metal fabrication services.

Certifications

DFMHUB is an ISO 9001: 2015 certified company and our Our manufacturing partners are (ISO 9001, ISO 14001, IATF 16949, ISO 27001)Certified.

Our latest Clients

FAQ

Sheet metal fabrication is a manufacturing method that involves include laser cutting, water jetting, plasma cutting, bending, punching, welding, and post-processing, sheet metal cutting, and bending sheets of metal to form different shapes.

Sheet metal fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness, and it’s suitable for prototyping and mass production runs.

Available materials for sheet metal

Aluminum : 6061, 6063, 5052, 5754

Stainless steel : 202, 304, 316

Ms – En8, En24, 1018, C9

Copper – Commerical & EC Grade

- Powder coating : Powder coating is a strong, wear-resistant finish that is compatible with all metal materials.

- Electro Platting : We can plate different metals including Copper, Zinc, Tin, Nickel, Chromium. Electroplating is the electrolytic process of depositing a thin

layer of a different metal on the base material. - Anodizing : Parts are brushed and then anodized type II. Ideal for increasing the

corrosion resistance of the part. Typically results in a glossy color.