End to End metal stamping solutions.

DFMHUB provides high-quality stamping services using a range of aluminum, copper, and steel alloys. We perform all operations such as punching, holing, bending & forming.

Our Manufacturing Capabilities

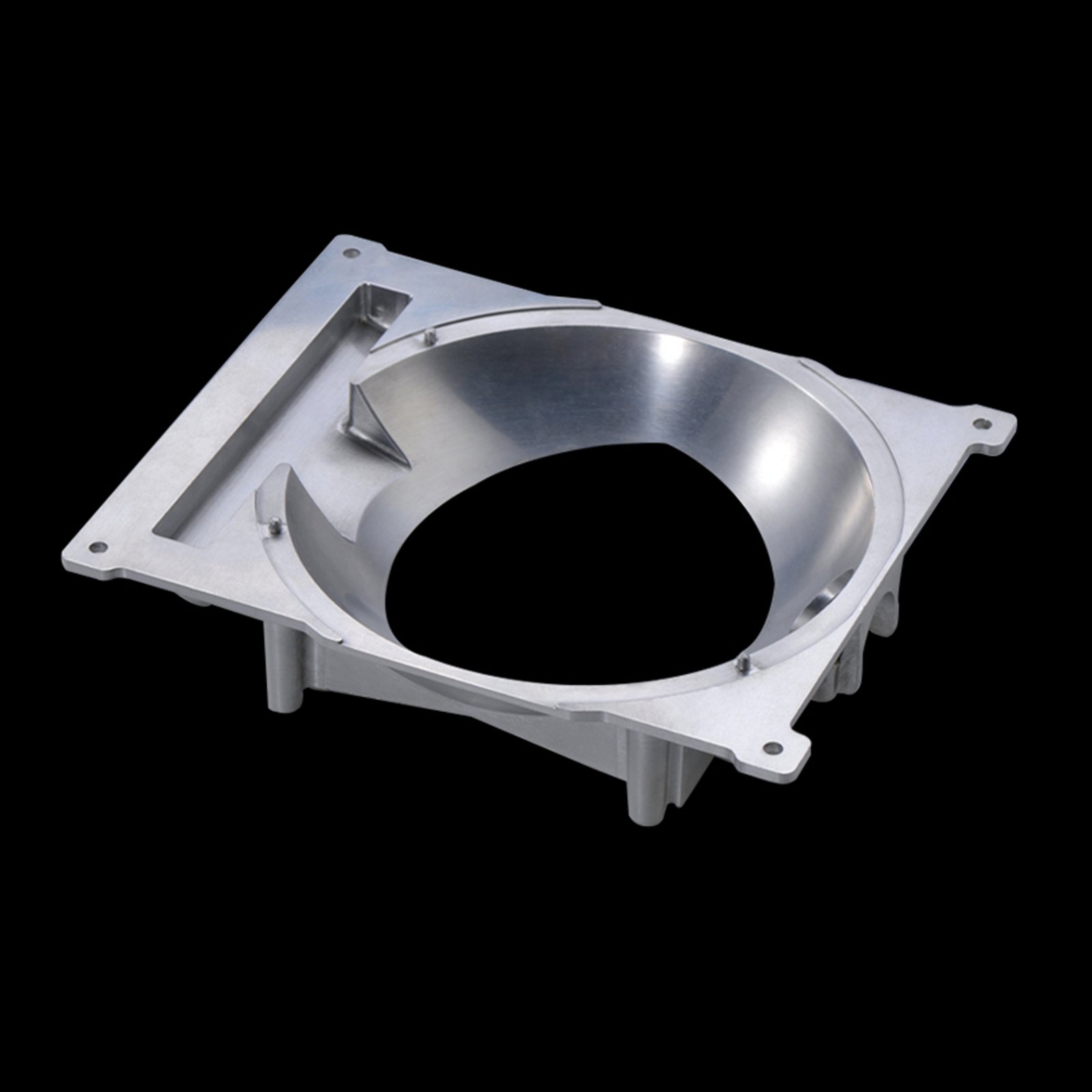

Deep drawing Stamping

Deep-drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions into a cavity, producing a closed bottom, round, or irregularly shaped cups.

Multi forming

Multi-forming is a novel manufacturing technique for three-dimensional sheet metal. This process is suitable for handling complex bending processes which are relatively difficult to achieve by conventional stampings

Progressive stamping

Progressive stamping is a process that encompasses punching, coining, bending, and several other ways of modifying metal raw material, combined with an automatic feeding system.

Prototype stamping

Prototyping is a short production run stamping used to prove out a design and make sure that the part, as designed, will perform as expected.

Your sheet metal stamping Partner

Materials Available

Aluminum : 6061, 6063, 5052, 5754, Stainless steel : 202, 304, 316 , MS – En8, En24, 1018, Copper – Commerical & EC Grade

Stamping Partners

Get to choose from our distributed network of sheet metal stamping partners across India.

Parts Manufactured

No of parts manufactured through our network of sheet metal stamping services.

Certifications

DFMHUB is an ISO 9001: 2015 certified company and our Our manufacturing partners are (ISO 9001, ISO 14001, IATF 16949, ISO 27001)Certified.

Our latest Clients

FAQ

Stamping is the process of pressing sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into the desired shape.

Stamping includes a variety of processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single-stage operation where every stroke of the press produces the desired form on the sheet metal part.

Available materials for sheet metal

Aluminum : 6061, 6063, 5052, 5754

Stainless steel : 202, 304, 316

Ms – En8, En24, 1018,

C9Copper – Commerical & EC Grade

- Powder coating: Powder coating is a strong, wear-resistant finish that is compatible with all-metal materials.

- Electro Platting: We can plate different metals including Copper, Zinc, Tin, Nickel, Chromium. Electroplating is the electrolytic process of depositing a thin layer of a different metal on the base material.

- Anodizing: Parts are brushed and then anodized type II. Ideal for increasing the corrosion resistance of the part. Typically results in glossy color.